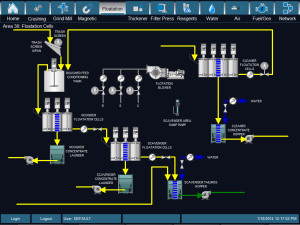

SCADA automation and process control is the foundation behind the projects Flotation processing facility. In the process crushed gold ore powder is mixed with water, frothing and collecting reagents. Air is then introduced to the mixture where minerals are caught on the surface of the bubbles rising to a froth on the surface. The froth is removed from the surface either by blowers or skimming very similar to separation processes used in the treatment of wastewater. Further removal of water and chemical reagents results in the product, a gold bearing concentrate.

The flotation processing facility and process control system is expected to produce a gold bearing concentrate with a grade of at least 50g/tonne Gold.

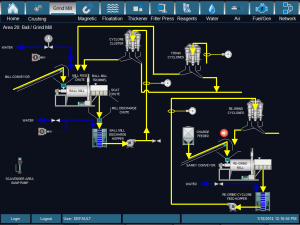

HMI Grind Mill Overview

- HMI development based on Rockwell PanelView Plus components integrated with various Rockwell PLC platforms. The HMI will monitor and control the processing facility including, crushing, grind mill, magnetic separation, flotation, reagent dosing, water, air, diesel and generation. Operators will be able to trend any variable in real time, monitor and acknowledge alarm conditions and operate plant.

- Rockwell PLC integration with a number of Deep Sea Electronics (DSEGenSet) generator controllers utilising Modbus protocol.

HMI Flotation Overview

Rockwell PanelView HMI

Pingback: HMI Development - integratedSCADA